Consulta la nostra informativa Privacy & Cookie Policy

Come funziona

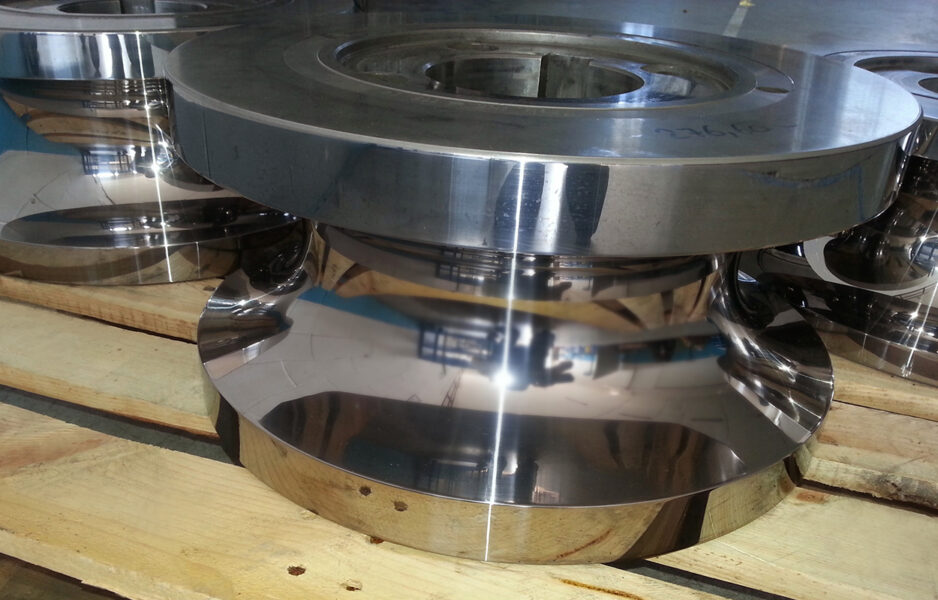

HVOF è l’acronimo di High Velocity Oxygen Fuel, una tecnica di deposizione a spruzzo da polveri che permette, a costi ridotti, di migliorare le caratteristiche superficiali di un materiale e di prolungarne la durata, anche in ambienti di lavoro particolarmente corrosivi e usuranti. Questo risultato è generalmente ottenibile senza interferire con le caratteristiche meccaniche e strutturali del substrato e quindi senza la necessità di ulteriori trattamenti.

Il rivestimento finale è caratterizzato da alta densità e elevata forza di legame, caratteristiche che garantiscono un incremento del grado di ancoraggio del riporto, una durezza elevata, una riduzione di eventuali porosità, limitato livello di rugosità superficiale e alta resistenza all’usura. Il processo fa uso di una miscela di combustibili: il cherosene brucia con un’elevata percentuale di ossigeno e produce una fiamma la cui velocità del flusso dei gas supera i 2000 m/sec.

In questo flusso vengono iniettate radialmente le polveri metalliche che vengono immediatamente fuse ed accelerate sino a circa 1000m/sec. Una volta impattato il substrato, le particelle solidificano rapidamente dando luogo, grazie all’elevata energia cinetica posseduta, a strutture lamellari.